Location: Home → Products → Silicone foam tube strip

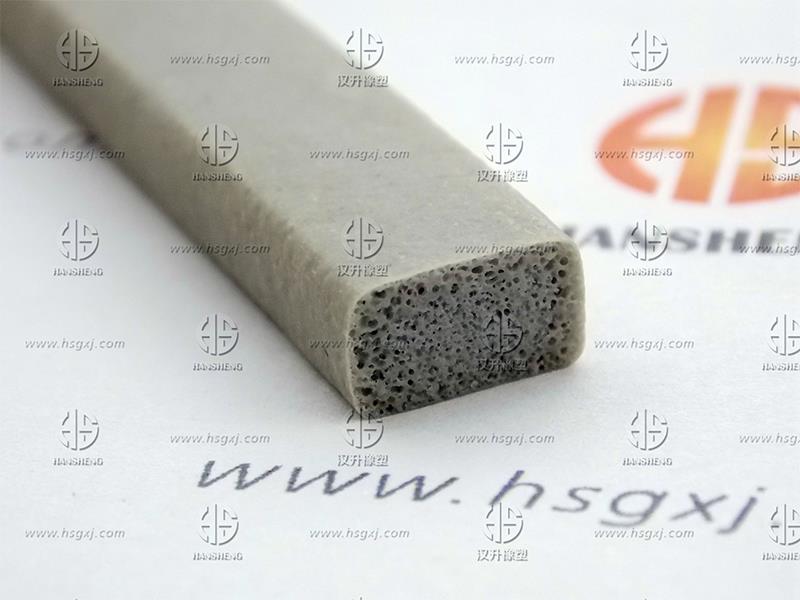

Foam sealing strip

features1. The product density of foam tube can be 0.5 ~ 0.85. Soft and light texture, good resilience, strong tensile force. It has excellent heat resistance to air aging, ozone resistance, insulation, and resistance to fuel oil and lubricating oil. It can work in the air or oil medium at the temper…

features

1. The product density of foam tube can be 0.5 ~ 0.85. Soft and light texture, good resilience, strong tensile force. It has excellent heat resistance to air aging, ozone resistance, insulation, and resistance to fuel oil and lubricating oil. It can work in the air or oil medium at the temperature of -60~+250℃.

2. Strong sealing ability, can effectively prevent small particles and rain.

3. Seal, dust proof, moisture proof, air tight and light shading, vibration isolation, fire prevention

4. Vibration isolation used in electronic equipment and vehicle interior

5. It can be used for punching all kinds of sealing gaskets and gaskets with strict requirements

6, in the wet water or temperature rise, the change is small, even if the silicon dioxide generated by short circuit combustion is still an insulator, which ensures that the electrical equipment continues to work, so it is suitable for the production of wire, cable, wiring.

Performance Parameters

1, with three anti - water, anti - UV function, can be used in the outdoor for a long time.

2. Insulation class: H class

3, power frequency voltage: greater than or equal to 15KV/mm

4. Tensile fracture strength: 3.5Mpa

5. Elongation at break: 480%

6, tear strength: 12KN/M

7. Brinell hardness: 35.5 degrees

8. Relative density: 0.85 oz. 0.5g/cm³

9, performance test method Typical value Physical performance color: white red yellow gray red black brown orange

Pressure deflection, psi (kPa) at 25% deflection measured by ASTM D 1056 force

Compression deformation, maximum % ASTM D 1056 test D<1 at 158ºF (70ºC) ASTM D 1056 test D< 5 at 212ºF (100ºC) Tensile strength, psi (kPa)ASTM D 412 45 (310) Elongation, % ASTM D 41280 Flame retardancy and gas release

Flame retardant UL94 V-0 and HF-1 class Flame Diffusion Index (Ls)ASTM E 162<25 Smoke Density (Ds)ASTM E 662 at 4.0 min test <50 at 1.5 min test <20 Toxic gas emission class SMP-800CPASS

1. The product density of foam tube can be 0.5 ~ 0.85. Soft and light texture, good resilience, strong tensile force. It has excellent heat resistance to air aging, ozone resistance, insulation, and resistance to fuel oil and lubricating oil. It can work in the air or oil medium at the temperature of -60~+250℃.

2. Strong sealing ability, can effectively prevent small particles and rain.

3. Seal, dust proof, moisture proof, air tight and light shading, vibration isolation, fire prevention

4. Vibration isolation used in electronic equipment and vehicle interior

5. It can be used for punching all kinds of sealing gaskets and gaskets with strict requirements

6, in the wet water or temperature rise, the change is small, even if the silicon dioxide generated by short circuit combustion is still an insulator, which ensures that the electrical equipment continues to work, so it is suitable for the production of wire, cable, wiring.

Performance Parameters

1, with three anti - water, anti - UV function, can be used in the outdoor for a long time.

2. Insulation class: H class

3, power frequency voltage: greater than or equal to 15KV/mm

4. Tensile fracture strength: 3.5Mpa

5. Elongation at break: 480%

6, tear strength: 12KN/M

7. Brinell hardness: 35.5 degrees

8. Relative density: 0.85 oz. 0.5g/cm³

9, performance test method Typical value Physical performance color: white red yellow gray red black brown orange

Pressure deflection, psi (kPa) at 25% deflection measured by ASTM D 1056 force

Compression deformation, maximum % ASTM D 1056 test D<1 at 158ºF (70ºC) ASTM D 1056 test D< 5 at 212ºF (100ºC) Tensile strength, psi (kPa)ASTM D 412 45 (310) Elongation, % ASTM D 41280 Flame retardancy and gas release

Flame retardant UL94 V-0 and HF-1 class Flame Diffusion Index (Ls)ASTM E 162<25 Smoke Density (Ds)ASTM E 662 at 4.0 min test <50 at 1.5 min test <20 Toxic gas emission class SMP-800CPASS

Hot News